Views: 1 Author: Site Editor Publish Time: 2025-03-19 Origin: Site

In a world where convenience, sustainability, and efficiency are paramount, food container factories play a critical role in meeting the growing demand for innovative and reliable food storage solutions. These factories are the unsung heroes behind the containers that keep our food fresh, reduce waste, and make our lives easier. From plastic and glass to stainless steel and eco-friendly materials, food container factories produce a wide range of products that cater to diverse consumer needs. This article explores the inner workings of food container factories, their impact on the industry, and how they are adapting to meet the challenges of a rapidly changing world.

The Role of Food Container Factories

Food container factories are responsible for designing, manufacturing, and distributing the containers that store and transport food. Their role extends far beyond production—they are at the forefront of innovation, sustainability, and quality control. Here’s how they contribute to the food storage industry:

Meeting Consumer Demand

Food container factories produce a wide variety of containers to meet the diverse needs of consumers. From lunchboxes and snack containers to large storage bins, they ensure that there is a product for every purpose.

Driving Innovation

These factories are hubs of innovation, constantly developing new materials, designs, and technologies to improve the functionality and sustainability of food containers. For example, many factories are now producing containers with smart features, such as freshness sensors and portion control compartments.

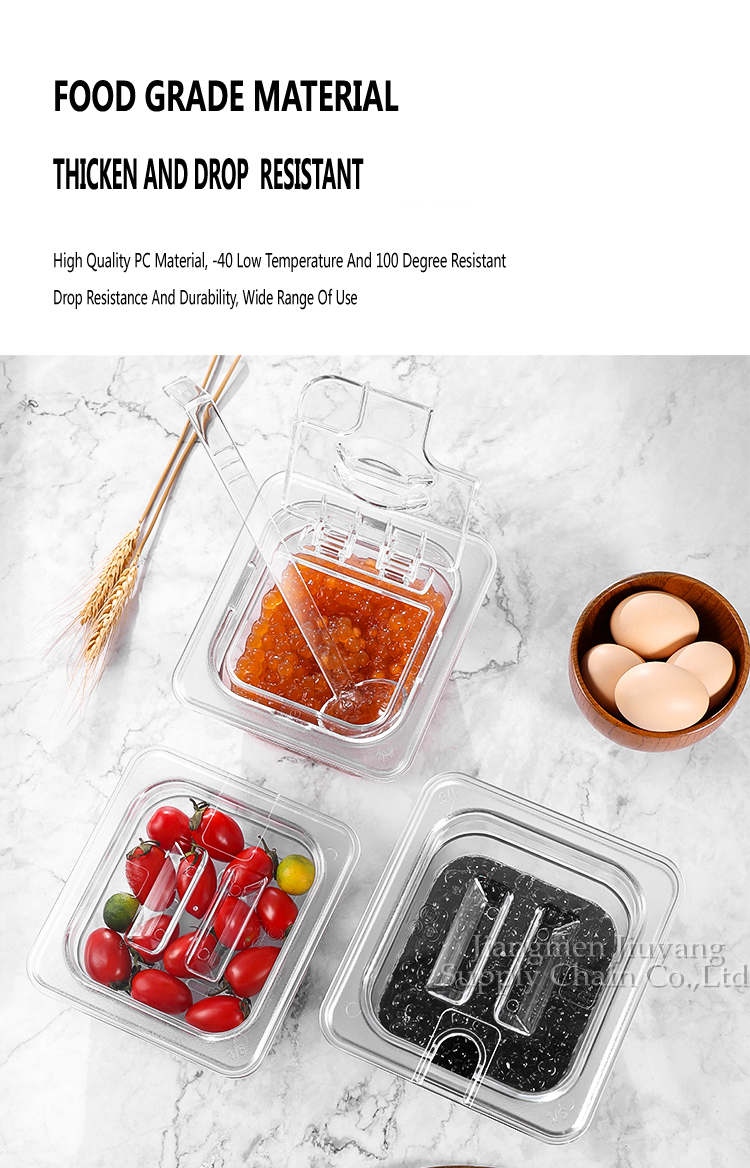

Ensuring Quality and Safety

Food container factories adhere to strict quality control standards to ensure that their products are safe, durable, and reliable. This includes testing materials for toxicity, durability, and resistance to heat and cold.

Promoting Sustainability

As environmental concerns grow, food container factories are increasingly focusing on sustainable practices. This includes using recycled materials, developing biodegradable options, and reducing waste in the manufacturing process.

The Manufacturing Process

The production of food containers involves several steps, each requiring precision, expertise, and advanced technology. Here’s an overview of the typical manufacturing process in a food container factory:

Design and Prototyping

The process begins with the design phase, where engineers and designers create prototypes of new containers. This involves considering factors such as functionality, aesthetics, and material selection.

Material Selection

Food container factories use a variety of materials, including plastic, glass, stainless steel, silicone, and eco-friendly alternatives. The choice of material depends on the intended use of the container and consumer preferences.

Molding and Shaping

Once the design and materials are finalized, the containers are molded and shaped using advanced machinery. For example, plastic containers are often made through injection molding, while glass containers are formed using blow molding techniques.

Assembly and Finishing

After molding, the containers are assembled and finished. This may involve adding lids, handles, or other components. The containers are then inspected for quality and durability.

Packaging and Distribution

The final step is packaging the containers for distribution. Food container factories ensure that the products are securely packaged to prevent damage during transit. They are then shipped to retailers, wholesalers, or directly to consumers.

Types of Food Containers Produced

Food container factories produce a wide range of products to cater to different needs and preferences. Here are some of the most common types of containers they manufacture:

Plastic Containers

Plastic containers are lightweight, durable, and affordable, making them a popular choice for everyday use. Factories produce a variety of designs, from small snack containers to large storage bins.

Glass Containers

Glass containers are known for their durability and eco-friendliness. Factories produce glass containers in various shapes and sizes, often with airtight lids for optimal freshness.

Stainless Steel Containers

Stainless steel containers are durable, rust-resistant, and ideal for packing lunches. Factories often produce these containers in modular designs, making them perfect for bento boxes.

Silicone Containers

Silicone containers are flexible, heat-resistant, and easy to store. Factories produce silicone containers in a variety of shapes, including collapsible designs for space-saving storage.

Eco-Friendly Containers

With the growing demand for sustainable products, factories are increasingly producing eco-friendly containers made from materials like bamboo, wheat straw, and biodegradable plastics.

Specialty Containers

Factories also produce specialty containers designed for specific purposes, such as salad containers with separate dressing compartments or insulated soup containers.

The Impact of Food Container Factories on Sustainability

Food container factories are playing a crucial role in promoting sustainability within the food storage industry. Here’s how they are making a difference:

Reducing Plastic Waste

Many factories are shifting away from single-use plastics and focusing on reusable and recyclable containers. This helps reduce plastic waste and its impact on the environment.

Using Sustainable Materials

Factories are increasingly using sustainable materials, such as recycled plastics, biodegradable polymers, and natural fibers. These materials are eco-friendly and reduce the reliance on non-renewable resources.

Implementing Green Manufacturing Practices

Food container factories are adopting green manufacturing practices, such as reducing energy consumption, minimizing waste, and using renewable energy sources. This helps lower their carbon footprint and promote environmental responsibility.

Encouraging Consumer Behavior

By producing durable, reusable containers, factories are encouraging consumers to adopt more sustainable habits. This includes reducing food waste, avoiding single-use plastics, and choosing eco-friendly products.

Challenges Faced by Food Container Factories

Despite their importance, food container factories face several challenges in today’s competitive and rapidly changing market:

Rising Material Costs

The cost of raw materials, such as plastic and glass, can fluctuate significantly, impacting production costs and profitability.

Environmental Regulations

Factories must comply with strict environmental regulations, which can increase operational costs and require significant investments in sustainable practices.

Consumer Preferences

Keeping up with changing consumer preferences and trends can be challenging. Factories must continuously innovate and adapt to meet the demands of a diverse and discerning market.

Global Competition

The food container industry is highly competitive, with factories around the world vying for market share. This requires factories to maintain high standards of quality and efficiency.

The Future of Food Container Factories

As the world continues to prioritize sustainability and innovation, the future of food container factories looks promising. Here are some trends to watch for:

Smart Containers

Factories are increasingly producing smart containers equipped with sensors and tracking technology. These containers can monitor food freshness, track expiration dates, and even suggest recipes based on the ingredients stored inside.

Biodegradable and Compostable Options

The demand for biodegradable and compostable food containers is growing. Factories are investing in research and development to create containers made from natural materials that break down easily.

Customization and Personalization

Personalized food containers with custom designs, colors, and features are becoming more popular. Factories are leveraging advanced manufacturing techniques to offer consumers unique and tailored products.

Automation and Robotics

Automation and robotics are transforming the manufacturing process, making it more efficient and cost-effective. Factories are adopting these technologies to increase production capacity and improve quality control.

Conclusion

Food container factories are the backbone of the food storage industry, producing the containers that keep our food fresh, reduce waste, and make our lives easier. From plastic and glass to stainless steel and eco-friendly materials, these factories are at the forefront of innovation and sustainability. As consumer preferences and environmental concerns continue to evolve, food container factories are adapting to meet the challenges of a rapidly changing world. By embracing new technologies, sustainable practices, and innovative designs, they are shaping the future of food storage and contributing to a more sustainable and efficient way of living. Whether you’re packing lunch, storing leftovers, or organizing your pantry, the products from food container factories are the unsung heroes that make it all possible.